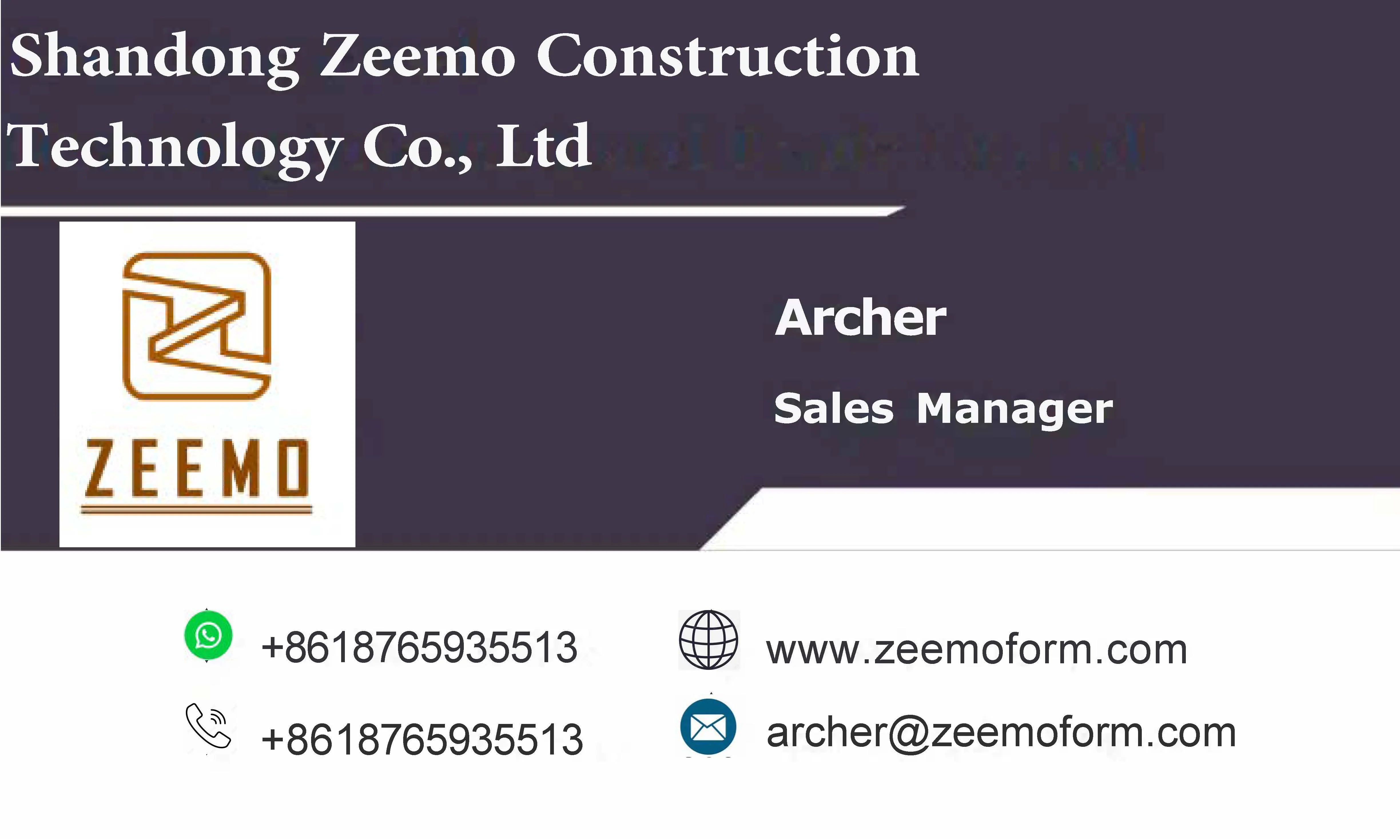

Q1: Are you trading company or manufacturer?A1: We are factory in ShanDong, China. Q2: Do you provide samples? Is it free or extra? A2: sample is rechargeable, also the freight. Q3: What is your terms of payment?A3: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance against copy B/L.Q4: What services can we provide?A4: Accepted Delivery Terms: FOB, CFR, CIF, EXW, etc.; Accepted Payment Currency: USD, EUR, CNY; Accepted Payment Type: T/T, L/C.

Q5: What can we bring to you?

A5: Our engineering team can excellently complete the technical solution design for you!

Our factory can perfect produce of the desired products!

Our high-quality products enable you to succeed!

Our support team can solve any problems along the way!

We are honored to answer any questions you may have, please contact us.